D341X Gear-Operated Flanged Butterfly Valve Series

manufacturer: Kaiweixi Valve Group Co., Ltd

Eml: Carrie@kaiweixi.com

Tel: +86 (577) 67038872

Mob: +86 189 6779 6392(WeChat Same Account)

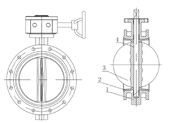

product drawing

D341X Gear-Operated Flanged Butterfly Valve Series

Overview

The D341X Gear-Operated Flanged Butterfly Valve is a valve designed with flanged connections, utilizing a worm gear mechanism to drive the disc through a 90° rotation for opening, closing, and flow regulation. The centerline design of the valve body ensures uniform contact between the disc sealing surface and the seat, achieving bidirectional sealing through the compression deformation of a rubber or elastic polymer disc seal ring (or seat seal ring). The gear-operated transmission device (commonly referred to as a gearbox) amplifies manual operating torque, enabling smooth operation even for large-diameter valves. It also features a self-locking function to maintain the disc securely at any opening position. This valve is widely used for fluid pipeline control in industries such as water treatment, HVAC, water supply and drainage, energy, and chemical processing..

Features

1、Gear-Driven Operation with Low Effort: Utilizing a precision worm gear reduction mechanism, the valve delivers high output torque, enabling smooth and effortless opening and closing. It is particularly suitable for manual operation in pipelines with diameters above DN200. The integrated mechanical self-locking function prevents disc displacement caused by medium impact.

2、Compact Structure and Excellent Flow Characteristics: Designed with a centerline symmetrical construction and short face-to-face dimensions, the valve occupies minimal space. When fully open, the disc offers low resistance to flow, with the passage approximating the inner diameter of the pipeline, resulting in minimal pressure loss.

3、Bidirectional Sealing with Reliable Performance: The valve seat typically features an integral rubber or composite soft-seal structure, which closely mates with the disc edge. By rotating the disc to compress the sealing ring, the valve achieves bidirectional (or unidirectional, depending on design) zero-leakage sealing, providing excellent shut-off performance when closed.

4、Corrosion Resistance and Long Service Life: The interior and exterior surfaces of the valve body can be treated with anti-corrosion coatings such as epoxy resin. Key components, including the stem and worm gear, are manufactured from stainless steel or copper alloy, offering strong corrosion resistance and suitability for various water qualities and mildly corrosive media.

5、Flanged Connection for Secure Installation: Designed with standard flanged ends, the valve ensures easy alignment with pipeline flanges, high connection strength, and reliable sealing. It is convenient for installation and removal within existing piping systems.

6、Versatility and Expandability: The gear operator can be easily detached and replaced with electric or pneumatic actuators, enabling remote automatic control to meet the requirements of automated pipeline systems.

Dimensions & constructral diagram

D341X Gear-Operated Flanged Butterfly Valve Series constructral diagram(pic1)

The main technical parameters

| Names | Materials |

|---|---|

| Valve Body | QT450 |

| Rubber Lining | Nitrile Rubber (NBR) or Ethylene Propylene Diene Monomer (EPDM) |

| Disc | QT450 |

| Stem | 3Cr13 |

Standard

| Item | Specification | Unit |

|---|---|---|

| Nominal Pressure | 1.6 | PN |

| Strength Test Pressure | 2.4 | - |

| Seal Test Pressure | 1.76 | - |

| Applicable Temperature Range | ≤80 | ℃ |

The main external and connection dimensions

| Nominal Diameter (DN) | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Dimension (L) | 108 | 112 | 114 | 127 | 140 | 140 | 258 | 165 | 178 | 190 | 216 |